This is the narrative of how extra virgin olive oil is produced. We pressed our olive oil at Frantoi Covato, a company located in San Giacomo, within the province of Ragusa, Sicily. This oil mill has been pressing olives since 1985. Today, it is run and operated by brothers Orazio and Giuseppe Covato, who are hands-on in the entire operation. Many thanks to them and their employees for their help and assistance with this story.

Frantoi Covato specialises in the cold pressing of olives. Cold extraction is a traditional method of extracting oil from olives. It is a mechanical process that does not involve the use of heat or chemicals. The indication “cold extraction” may appear only for virgin or extra virgin olive oils obtained at a temperature below 27°C (80.6°F). The resulting extra-virgin olive oil is pure and unrefined, with all its natural nutrients and antioxidants intact. This is the type of olive oil that is associated with the Mediterranean diet.

The Covato oil mill runs from mid-September to mid-December. It has two separate lines and can process up to ten concurrent presses. The company serves a geographically wide area, and owners of olive groves of all sizes gravitate to this place during this period like moths to a flame. To serve clients, Frantoi Covato typically runs 12 hours a day, peaking at around 20 hours to meet demand.

Tonda Iblea, Moresca, and Verdese are the olive varieties that are grown in this region. These olives and the olive oil produced here carry the European Union DOP, IGP, and BIO food certifications.

DOP (POD in English) stands for Denominazione di Origine Protetta (Protected Designation of Origin) and indicates that a product owes its characteristics to its place of origin, and its production, modification, and processing occur within that geographical area. IGP (PGI in English) stands for Indicazione Geografica Tipica (Protected Geographical Indication) and identifies agricultural products for which their quality, reputation, or other important characteristic depends on their production, processing, and/or preparation taking place in a defined geographical area with at least one stage of production tied to the geographical location that has, over time, stood out for its quality and reputation. BIO means that the item was grown following the rules of the EU Regulation on Organic Farming. For processed foods, the label BIO means that at least 95% of the ingredients of agricultural origin come from organic farming (the EU allows the remaining 5% for external material carried by rain and wind). For a product to achieve the BIO mark, it must not use genetically modified or radiated products or products with additives or stabilisers. The Italian Ministry of Agriculture is responsible for these certifications.

The oil mill serves clients of all sizes. On the smaller side, one finds foreigners who own property with land that has olive trees. These typically visit every year around this time for the harvesting adventure. They normally consume the olive oil they produce and gift family and friends with bottles of “this year’s pressing." The more refined will even print decorative labels to mark the content and the vintage.

Other groups that press their oil are locals who have emigrated for economic reasons. It is customary, around this time, for children to gravitate to their parent’s house to help with the olive harvest and, over typical Ragusan meals, catch up with siblings. Three and sometimes four generations cram into a house for a few days. At the end of this adventure, everyone has caught up on the latest gossip, contributed their own, and will be returning home with a few bottles of nectar from “our land.”

Small harvesters typically bring in their harvest in their own crates. Upon arrival, they transfer the olives into the crates provided by the company. Larger producers load empty crates onto their trucks and return with them filled with olives. They repeat this undertaking daily until all the trees have been harvested. A crate holds 350kg of olives.

Small producers normally remain with their harvest until the pressing is complete. On the other hand, large producers deposit the filled crates, allowing Covato employees to manage the process. They have their own olive oil storage tanks, which they transport to their premises when full. It is quite impressive to see walls of crates waiting to be processed. Typically, the crates will be processed within an hour of being deposited. Producers process the olives within 6 hours of collection to ensure optimal quality.

During 2023, the company upgraded its equipment. The upgrade increased the processing speed, thereby reducing the loss of polyphenols and antioxidants during processing.

The Process

Every client is assigned a reference. Their crates are transported using a forklift from the waiting area to the weighing scales. An automated system will record the weight since this will be used to compute the yield. Typically, 100 kg of olives will produce between 10 and 15 litres of oil. Factors such as tree age, variety, climate conditions during the year, and other actions such as pruning impact the yield. Another factor that determines yield is the level of maturity of the olives. Green olives produce a lower yield but a more intense taste compared to brown olives pressed later in the season.

After the weighing, the forklift takes each crate and empties it into a unit that separates any olives still attached to a stalk, removes any debris, washes the olives, and dries them.

Leaves and other debris are automatically shuttled out into containment bins, where they will be disposed of. The olives are deposited in a hop for the next stage of processing. The process takes around 2 minutes per 350kg.

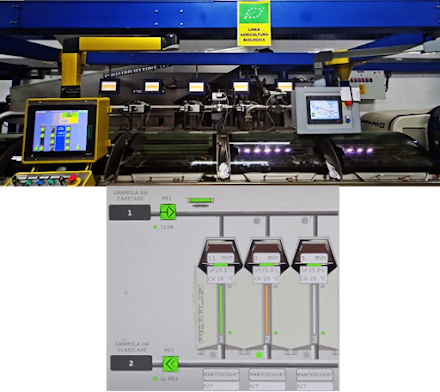

The olives are then ground up into a paste, and the mixture is moved into a holding tank, where it's transferred to one of the fermenting units. The fermenting units are used to bring out the flavour of the oil. The process is fully automated, requiring the operator to programme the transfer to a vacant unit using a touch screen.

In the fermenters, the paste is constantly aerated and rotated, and its temperature is controlled to ensure that the aroma is maximised. The duration of the process is programmed into the system, and the fermenters use coloured LEDs to visually indicate the progress of the fermentation process.

Once the fermentation process is complete, the paste is transferred into a temporary holding area and then into the protoreactor. The protoreactor separates the oil from the water and the solids. The water is discarded, while the solid components are transported via underground ducts to holding areas where they will be transformed into compost. This device minimises the time the paste is processed, as this ensures that flavour is preserved, maximises the antioxidant activity of the phenol compounds, and results in the best oxidative stability.

The protoreactor removes 90% of the water and more than 99% of the solids. A primary passive filtration unit, a centrifuge, and a secondary passive filtration unit remove the remaining water and solids.

Freshly pressed extra virgin olive is opaque because suspended in the oil is sediment. It is referred to as non-filtered. It is emerald-green in colour, and the smell is simply incredible. The temptation to divert some of the flow into a saucer and soak up all this goodness with Modican bread is immense. Anyone who has pressed olive oil at least once would have done so upon arriving home, if not at the mill. Some use this as a justification to "sample" the quality of the oil. The temperature of the oil is in the low to mid-20°C (68°F).

The size of the container into which the freshly pressed extra virgin olive oil is collected depends on the quantity of olives that are being pressed. The range varies from 3-litre, one-time-use jerry cans to reusable stainless-steel tanks that store thousands of litres. The commercial producers replace the air in their tanks with food-grade nitrogen to ensure that the oxygen in the air does not react with the oil.

The yield is computed by comparing the net weight taken at the start of the process to the quantity of olive oil collected at the end.

Over a few weeks, the sediment in non-filtered oil will settle to the bottom, leaving the semi-transparent golden-green liquid one typically associates with olive oil. This sediment is known as morchia in Italian. Those who have access to freshly pressed oil can use the product while it is still enriched with sediment. Once the sediment forms, the morchia is discarded.

Producers bottling the oil to be sold commercially filter the olive oil to remove any sediment prior to bottling. In the photo below, the filtering unit is seen on the left.

Producers bottling the oil to be sold commercially filter the olive oil to remove any sediment prior to bottling. In the photo below, the filtering unit is seen on the left.

Storing extra virgin olive oil

Olive oil should be stored in a cool place away from light and with as little oxygen as possible. Photos of the various screens shared here highlight how every stage of the cold pressing process is temperature-controlled. Storing olive oil in a hot environment will do to it what the mill worked hard to avoid. Likewise, light should be avoided by storing the oil away from direct light. A pantry that is dark and cool helps retain the taste and attributes of the oil.

Olive oil pressing is a fantastic experience, albeit a noisy one. Oil mills like those of the Covato brothers allow patrons to follow the process from a close yet safe distance. Anyone who is lucky enough to have olives for pressing will walk away with a greater respect for one of the staple products of the Mediterranean diet.

Additional interesting facts

|

No comments:

Post a Comment

Note: only a member of this blog may post a comment.